Have you ever wondered how the air suspension that supports a modified car's stunning stance is born from cold steel? Let’s take you into Maxload's production workshop and unveil the birth secret with these images!

Production Process Analysis

-

Laser Cutting - The Start of Precision

The laser beam carves sparks on the metal plate, like crafting a precise puzzle. This step shapes the metal components of the air suspension, with micron - level cutting precision to ensure every part fits perfectly—after all, there’s no room for error in suspension stability.

The laser beam carves sparks on the metal plate, like crafting a precise puzzle. This step shapes the metal components of the air suspension, with micron - level cutting precision to ensure every part fits perfectly—after all, there’s no room for error in suspension stability. -

Bending Process - Giving Structure Its Bones

The cooperation between the robotic arm and workers is like an industrial ballet, folding the cut metal plates into precise angles. This step determines the mechanical structure of the suspension components, a key foundation for "supporting the car's weight while adjusting the stance flexibly".

The cooperation between the robotic arm and workers is like an industrial ballet, folding the cut metal plates into precise angles. This step determines the mechanical structure of the suspension components, a key foundation for "supporting the car's weight while adjusting the stance flexibly". -

Welding Moment - A Firm Commitment in Sparks

The sparks from the welding torch twinkle like stars, and the worker's hands firmly hold the metal pipes. Each weld undergoes strict stress calculation to ensure it doesn't fail during long - term compression and extension—this is the hard - core guarantee of "durability".

The sparks from the welding torch twinkle like stars, and the worker's hands firmly hold the metal pipes. Each weld undergoes strict stress calculation to ensure it doesn't fail during long - term compression and extension—this is the hard - core guarantee of "durability". -

Precision Components - Details Speak Volumes

A greasy glove holds a newly finished small metal part, with visible precision in holes and edges. These seemingly insignificant "small parts" are the nerve endings of the air suspension control system, determining the response speed of stance adjustment.

A greasy glove holds a newly finished small metal part, with visible precision in holes and edges. These seemingly insignificant "small parts" are the nerve endings of the air suspension control system, determining the response speed of stance adjustment. -

Assembly - The First "Union" of the System

The arrangement of bolts and bearings at the junction of the metal base and air spring is meticulous. This is the core area of the air suspension's "up - down linkage", and the torque of each screw is calibrated repeatedly.

The arrangement of bolts and bearings at the junction of the metal base and air spring is meticulous. This is the core area of the air suspension's "up - down linkage", and the torque of each screw is calibrated repeatedly. -

Airbag Calibration - Balance Between Flexibility and Rigidity

Workers gently adjust the assembly details of the airbag. The airbag is the "soul organ" of the air suspension, and its elasticity and sealing directly determine the comfort when passing bumps and the smoothness of stance switching.

Workers gently adjust the assembly details of the airbag. The airbag is the "soul organ" of the air suspension, and its elasticity and sealing directly determine the comfort when passing bumps and the smoothness of stance switching. -

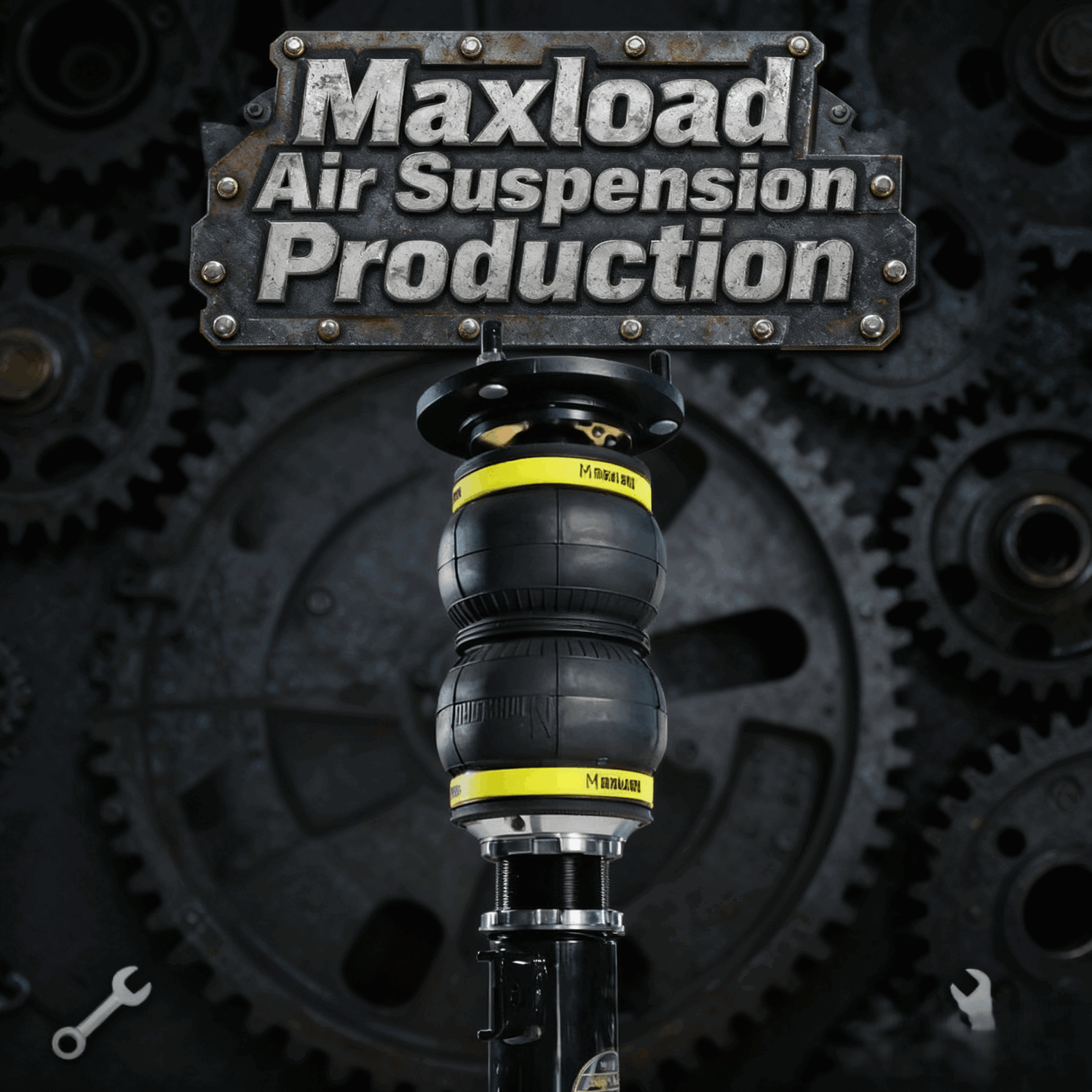

Prototype of the Finished Product - Presence Emerges

The complete air suspension assembly stands in the workshop, with the black - and - yellow airbag featuring Maxload's iconic design. It’s like a dancer about to take the stage, ready to show its versatile stances on the road.

The complete air suspension assembly stands in the workshop, with the black - and - yellow airbag featuring Maxload's iconic design. It’s like a dancer about to take the stage, ready to show its versatile stances on the road. -

Final Inspection - The Last Check on Quality

Precision instruments test the pressure and strength of suspension components to ensure every product leaving the factory can withstand the challenges of the road. This is Maxload's persistent commitment to "zero - defect quality".

Precision instruments test the pressure and strength of suspension components to ensure every product leaving the factory can withstand the challenges of the road. This is Maxload's persistent commitment to "zero - defect quality".

From the sparks of laser cutting to the presence of the finished suspension, every step embodies Maxload's dual pursuit of "ultimate stance and reliable performance". Next time you drive a car with Maxload air suspension, remember the story of "steel and fire" behind it.